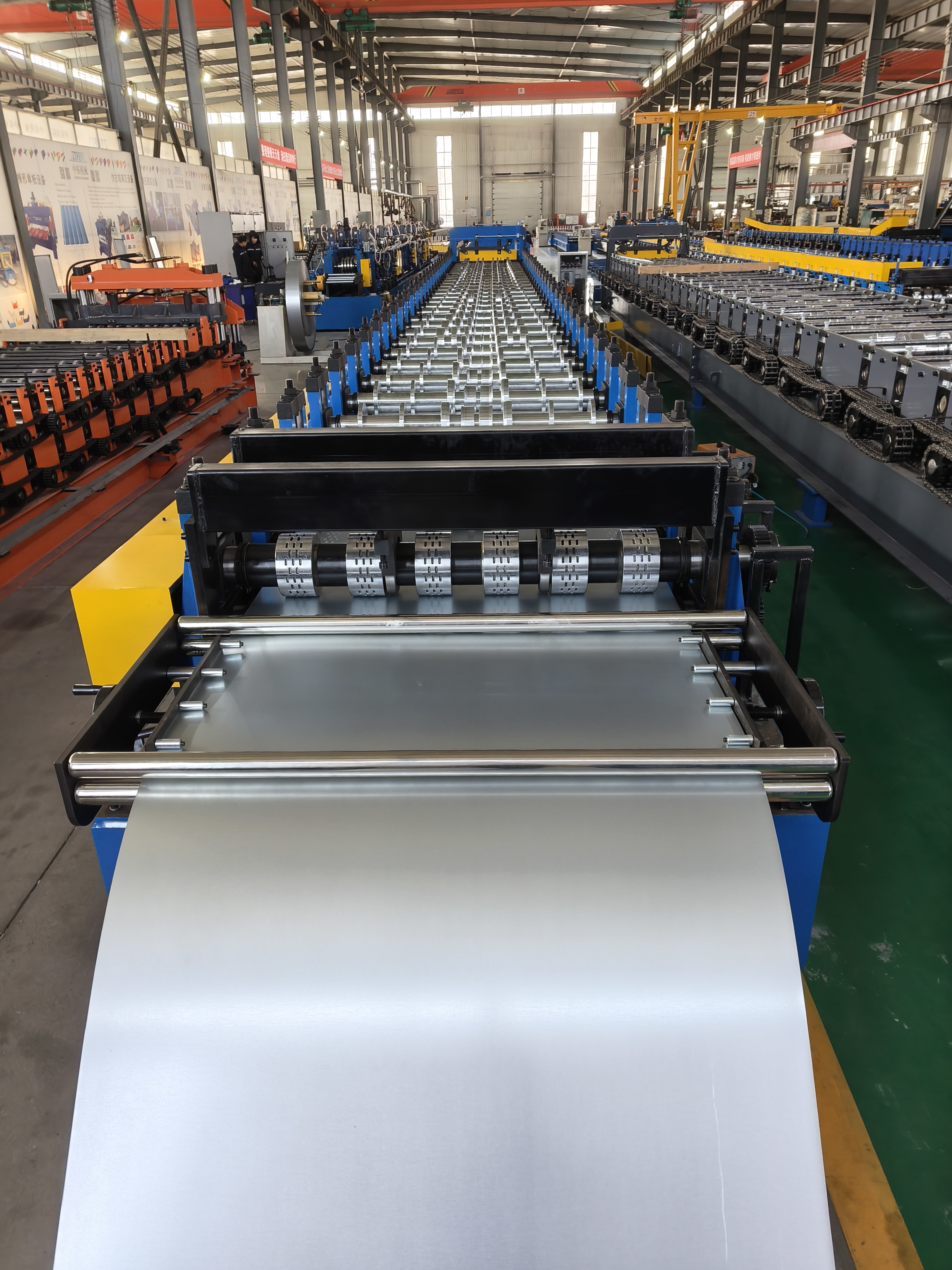

Metal roofing deck rolling machine

High speed metal roofing deck rolling machine produce speed can reach 25m/min and with gearbox drive type very steady,durable and good efficient, and our machine can protect materials surface very well, Zhongtuo roofing deck machne will be your best choose!

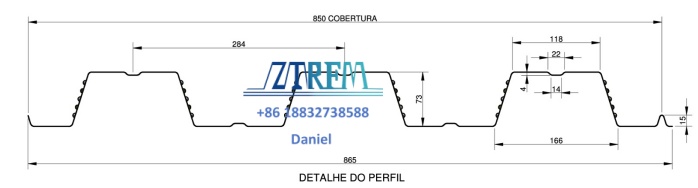

This machine production pattern drawing:

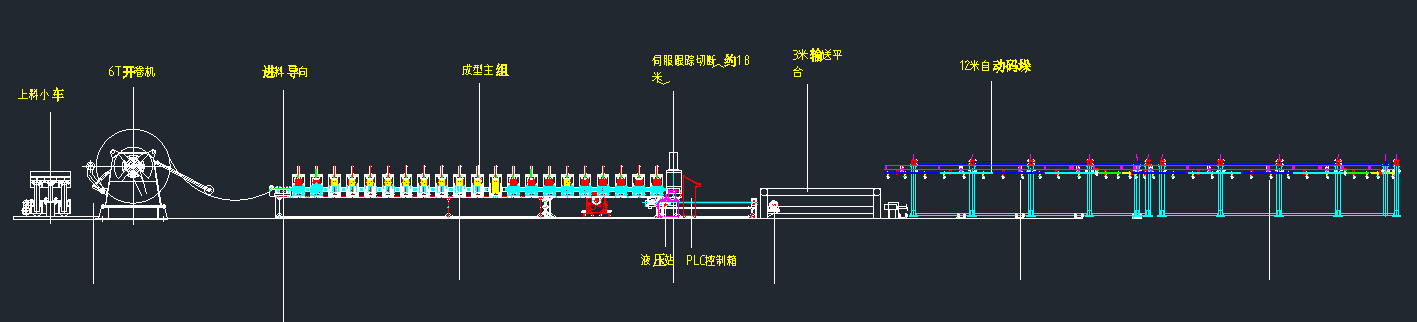

Machine working flow:

Machine Details

(1)15 T Hydraulic decolier with loading car

Decoiler type | Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension. |

Carrying capacity | 15 tons |

Loading car capacity | 15 tons |

Max coil width | 1300 mm |

Expand coil range | Φ508-φ600 mm |

Feeding speed | 0-45 m/min (adjustable) |

Driving motor power | 7.5 kw |

Hydraulic motor power | 4 kw |

Structure | welding by the steel plates and profiled bar. |

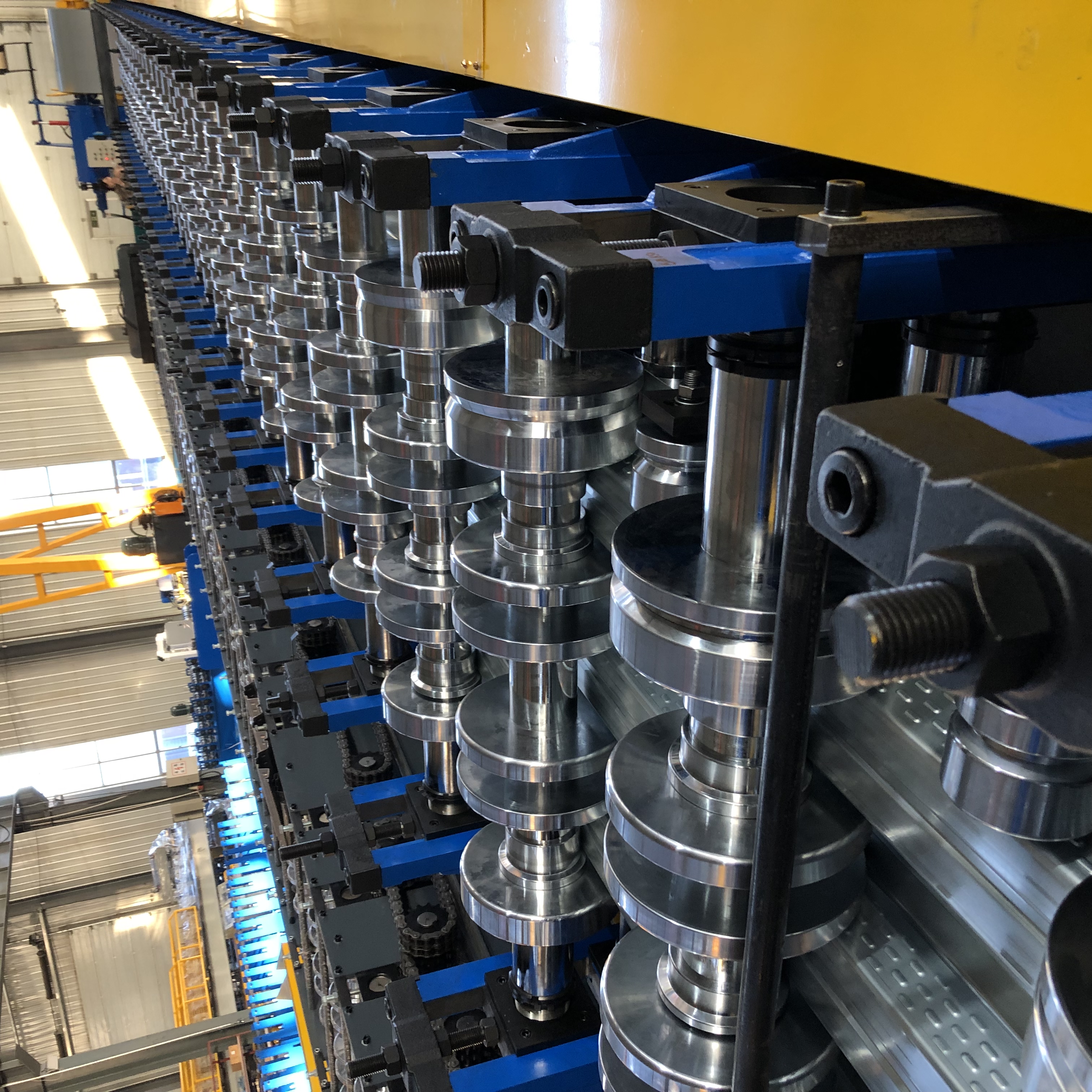

(2)Main roll forming machine

Machine frame | Cast iron archway ,high precision and better stability |

Material of rollers | High grade 45# forged steel and Cr15 |

Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

Forming stations | Roller stations :26 rows |

Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

Diameter of shafts | Φ95 mm solid |

Material of shafts | High grade 45#,with heat treatment |

Forming speed | 25 m/min |

voltage | 380V/60HZ/3P (as requested) |

Transmission way | By Chains |

Main motor | 11 KW *3 |

Cutting blade material | Gcr12 quenched treatment |

Cutting type | Stop cutting |

Cutting Driving method | By pillar type Cylinder |

(3) PLC control station

PLC brand:Siemens

Touched screen brand: Siemens

Frequency Converter: Yaskawa

Encoder brand:Omron

Electrical components:Schneider

Operating language:English and Chinese(or as requested)

You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

(4)Hydraulic Station

Hydraulic station motor:15KW + Accumulator

Hydraulic oil:46# hydraulic oil

Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

(5)Automatic Stacker

Stacking principle: the top sheet will not damage the sheet below, the profile of the sheet below will match the profile of the top sheet

1. Max. Length of the sheet: 9000 mm

2. Max. Width of the sheet: 1250 mm

3. The thickness of stack: 300 mm

4. Unloading Power: pneumatic (the air pump is provided by the user)

5. Stack table is moveable (left-right)

6. Transmission power:3 kw

7. Drive of transmission by 1.0 inch double line chains

8. Stacker dimension:6000m×2100mm×1600mm