Simple cut to length line for thin sheet metal operating speed 25 to 35 meter per minute

Simple cut to length line for thin sheet metal operating speed 25 to 35 meter per minute is designed to make the sheeting cutting easily and fast.

1. Operating speed of the entire line: 25 to 35 meter per minute

2. Maximum thickness of material passing: 0.35-2.0mm (1.5mm stainless steel)

3. Maximum width of material passing: 1600mm

4. Delivery direction: customer specified

5. Basic electrical parameters:

6. Basic parameters of air pressure: 5 kg/cm2

7. Suitable materials for use: galvanized iron sheet, galvanized aluminum sheet, cold iron sheet, aluminum sheet, etc.

8. Calculate using a material with a tensile strength of 400N/mm and a yield strength of 275N/mm.

The cut to length line is composed by the following elements:

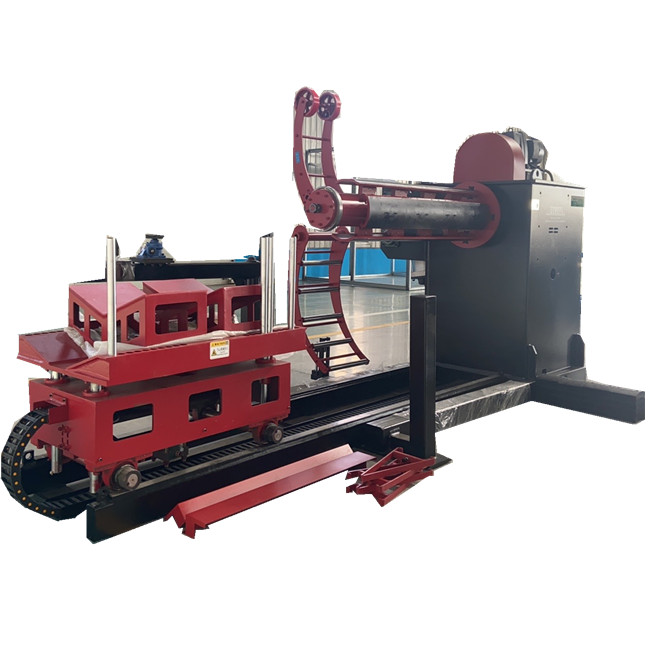

Item 1: 8 ton hydraulic decoiler.

Automatic material machine

Function: Used to support the discharge of coil materials.

Main structure: composed of frame, expansion component, spindle, pressure support arm component, hydraulic component, electric part, etc.

Rack: Made of ordinary carbon steel plate and square tube welded together, connected in series with the main shaft and two bearing seats welded together to ensure the main shaft

Concentric.

Expansion component: Expansion range diameter: ø 470mm - ø 530- φ 630mm, maximum width 1600mm, maximum outer diameter Φ The 1500mm four curved plates are connected to the main shaft through sliding expansion using sliders.

Spindle: processed by 45 # round steel quenching and tempering precision turning, with a load capacity of 8 tons.

Pressure support arm component: used to press the material tightly from the coil, assisting in feeding the material to the leveling feeder.

Hydraulic power: push-pull expansion and contraction core shaft.

Electrical power: variable frequency drive, 5.5KW motor with helical gear reducer and chain drive.

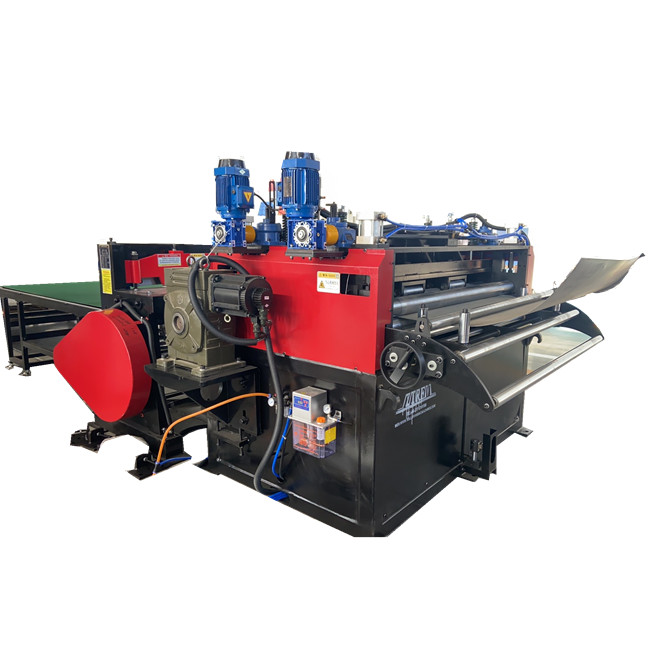

Item 2: Main leveling and servo coil feeder:

Function: Used for leveling materials and feeding materials of fixed length and size.

Main structure: leveling roller, electric part, and inlet and outlet support seat components.

Leveling roller: Made of 40Cr round steel quenched and tempered, processed with high frequency treatment, and subjected to two rounds of electroplating and external grinding, the surface is glossy and has no traces, making it hard

The degree reaches HRC62 or above.

Back pressure roller: quenched and tempered by 40Cr round steel, processed with high frequency treatment, after two electroplating and external grinding, the surface has no trace of gloss and hardness

Reaching HRC62 degrees or above.

Feeding roller: Made of 40Cr round steel quenched and tempered, processed with high frequency treatment, and subjected to two rounds of electroplating and external grinding, the surface is glossy and has no traces, making it hard

The temperature reaches HRC62 degrees, and pneumatic relaxation is used above.

Item 3: Motor cut to length machine

This machine tool has changed the transmission form of the mechanical shearing machine and is currently recognized as one of the most advanced small shearing machines both domestically and internationally. This machine

Drawing on advanced foreign technology, adopting pneumatic clutch and flywheel, the transmission mode is driven by an electric motor to operate the flywheel, and is subject to selective foot switch

The control adopts instantaneous engagement, with smaller shear angles and inclined shear directions, which minimizes the bending deformation of the workpiece. Knife. The adjustment of blade clearance adopts a manual quick adjustment device, which is very easy to obtain satisfactory blade clearance and is an ideal processing method for metal and non-metallic sheets

Cutting equipment.

Item 4: Convey table and stacker:

Rack: Made by welding square tubes and connected with linear guide rails for sliding material blocking.

Stacking component: assembled with carbon steel, the length and width of the material are controlled by T-shaped screw hand cranking to adjust the length and width of the material, Add pneumatic tapping device for length and width.

Function: Used for material transportation.

Main structure: frame, oil pressure system, discharge rolling platform, etc; Rack: Made of carbon steel welded together, it has the characteristics of stability and firmness. Scissor fork design, oil cylinder stretching and lifting. Discharge rolling platform: driven by an oil motor, the drive sprocket drives the drum to rotate to transport material discharge. Standard configuration is 1 platform for material delivery. Directional discharge can increase bi-directional discharge to improve production efficiency.

For this machine, if you want to know more information, please contact us at any time.