Changzhou Zhongtuo has demonstrated strong capabilities in the mid-range roofing machine segment through its balanced approach to cost efficiency, technical reliability, and responsive customer service. With proper strategic focus on digital transformation and market-specific adaptations, the company is well-positioned for continued global expansion.

1. Company Profile and Core Competencies

1.1 Organizational Background

Our Zhongtuo factory Established: 2009 (16 years of operation) and we has 12 years exports expirence in Alibaba

Our sales and factory Workforce: Approximately 100 employees

Zhongtuo factory Leadership: Founded by Mr. Cary Xu, a cold forming machine specialist since 2006

Global Reach: Equipment exported to 150+ countries, Furthermore, we utilize Siemens' intelligent interconnection system to consolidate machine after-sales services.

1.2 Zhongtuo factory core Strengths

We has specialized technical team with decades of combined experience

Integrated production from design to manufacturing

ISO-certified quality management systems

Multilingual sales and support capabilities

2. Roofing Sheet Machine Product Line Analysis

2.1Advanced Technical Features

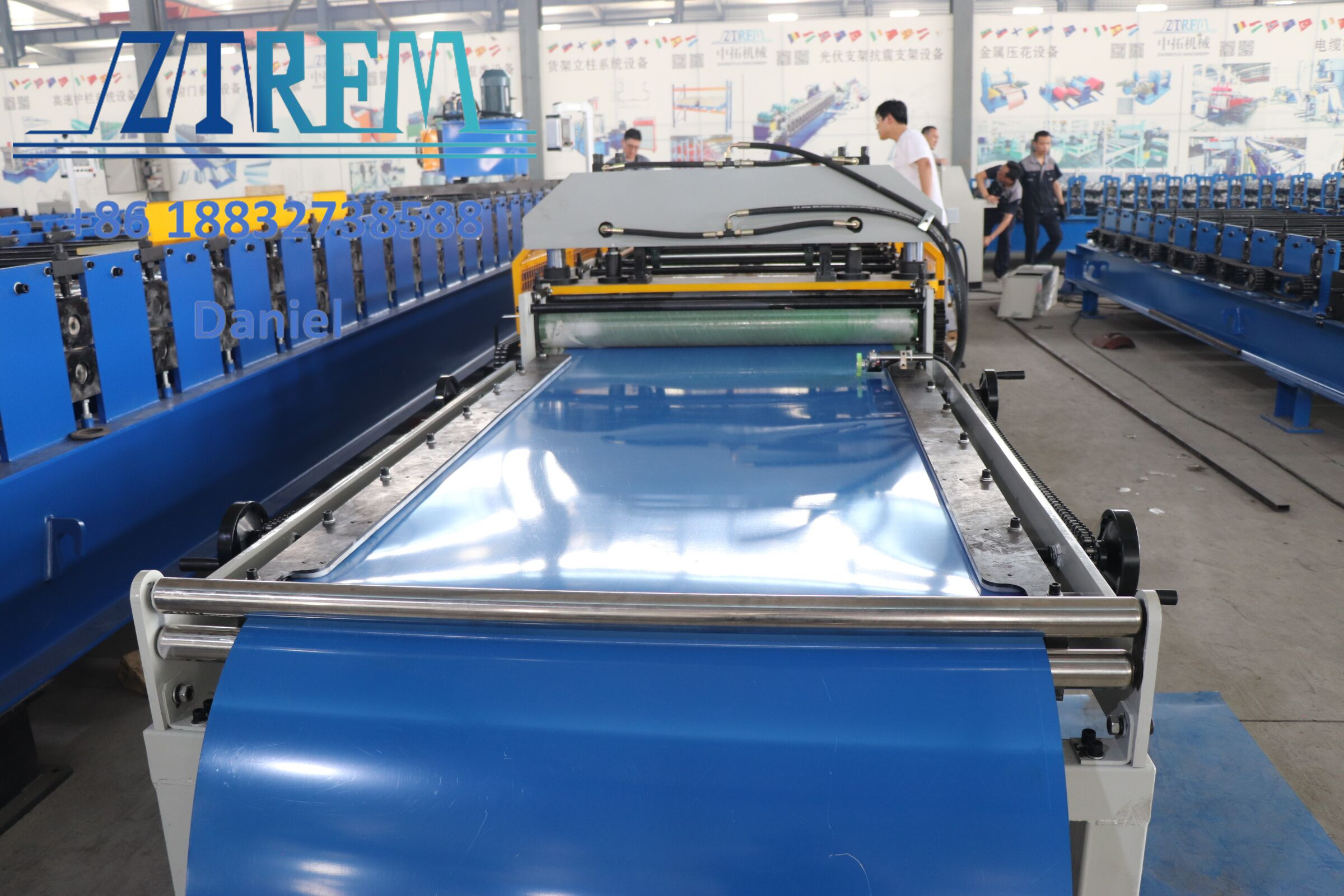

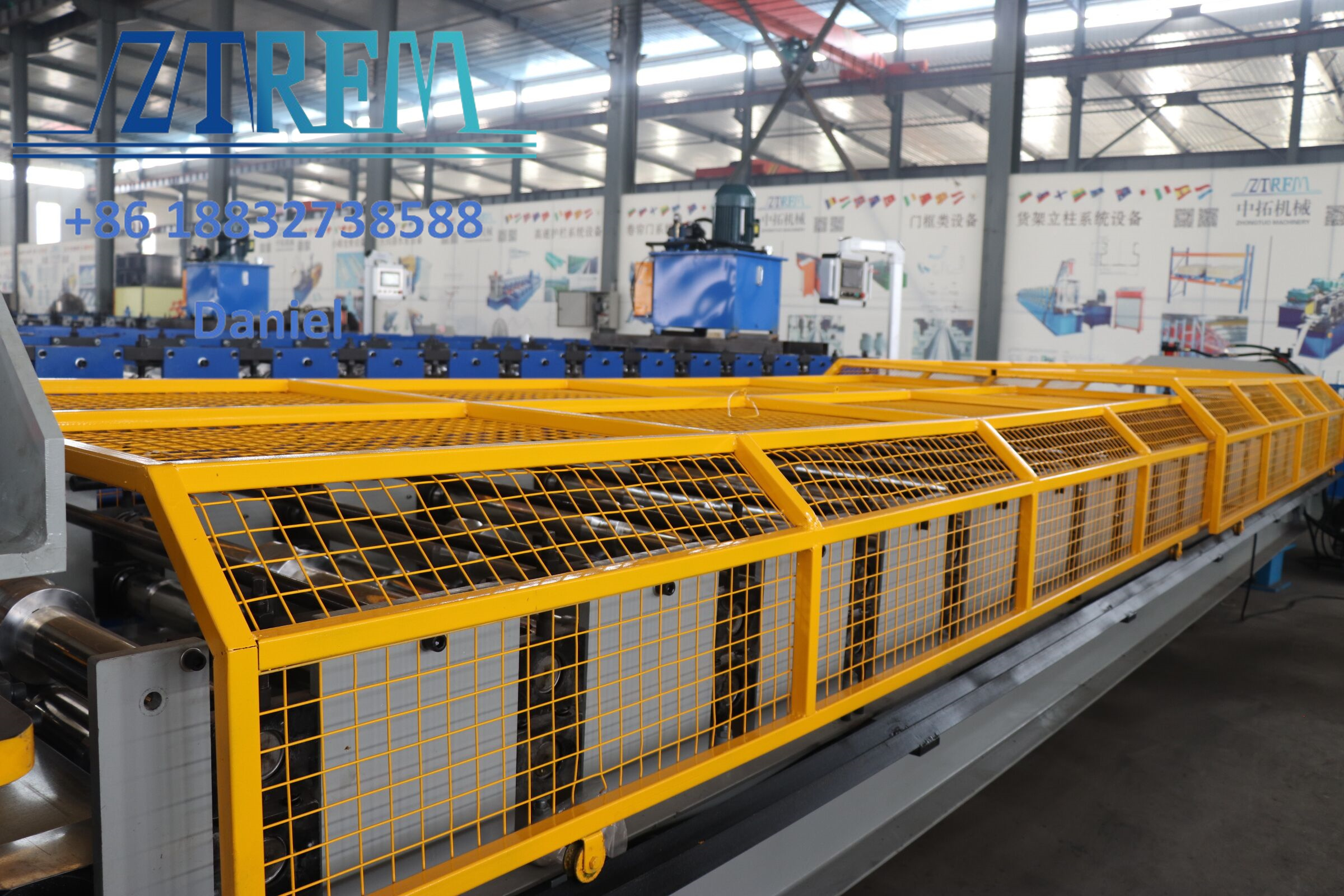

Precision Forming System

Computer-optimized roller path design

±0.15mm dimensional tolerance

Automatic thickness compensation

Smart Control Systems

Remote monitoring capabilities

Production data logging function

Durability Enhancements

Hard-chromium plated rollers (HRC 58-62)

Reinforced gearbox design

Automatic lubrication system

3. Production Capacity and Quality Assurance

3.1 Manufacturing Process

Vertical integration: 85% components made in-house

Lean production system

Our factory has profession producing part , and average machine lead time: 45-60 days

3.2 Quality Control Measures

Raw material inspection (SGS certified)

In-process dimensional checks

72-hour continuous test run before shipment

CE certification for European markets

4. Global Market Performance

4.1 Export Market Analysis

Localized machine adaptations

Regional service centers

Partner training programs

4.2 Competitive Advantages

Price-performance ratio (20-25% below European brands)

Customization flexibility (50+ standard profiles)

Quick-response technical support (48-hour online assistance)

5. Technology Development Roadmap

5.1 Current R&D Focus

AI-assisted profile design software

Energy-saving drive systems

Lightweight aluminum frame construction

5.2 Future Innovations

Predictive maintenance systems

Augmented reality operation guide

6. Challenges and Strategic Recommendations

6.1 Market Challenges

Increasing raw material costs

Stricter international certifications

Competition from second-hand equipment market

6.2 Development Suggestions

Expand patent portfolio

Enhance digital service platforms

Develop entry-level models for emerging markets

Strengthen OEM partnership