The coloured stone tile production line includes multiple processes such as cutting, pressing, spraying glue, sand coating, drying, and moulding. Coloured stone tiles are gradually becoming popular in construction markets across the country due to their beautiful retro appearance and durability and moisture resistance. Let's take a look at the highlights of Zhongtuo's production line!

Zhongtuo color coating roof tile machine unit can be divided into two stages: pre-degreasing and degreasing. The pre-degreasing section is usually set before the inlet loop of the unit. Its function is to remove most of the oil stains on the surface of the strip and prevent the strip from slipping and running in the inlet loop. Partial. The pre-degreasing section is simpler than degreasing. The pre-degreasing process is mostly used in large-scale high-speed units, and generally, small and medium-sized units are less equipped.Zhongtuo machine has passed international ISO, CE, CSA and other import certifications, making it a worthy choice!

The degreasing is located after the inlet looper. After the strip comes out of the inlet looper, it passes through the turning roller and enters the strip degreasing cleaning section for thorough surface cleaning. The purpose is to completely remove grease and dirt from the surface of the substrate. It is best to dry it with hot air to make the surface of the substrate very clean and wettable, ready for the next chemical liquid treatment. The cleaning agent must have a good dissolving, saponification, and emulsification effect on grease, and be able to absorb dirt. The cleaning effect is largely related to the process parameters of each process in the degreasing cleaning section and the structure of the equipment.

From technical and economic considerations, the degreasing of large color coating units usually uses alkaline cleaning agents instead of traditional acid and neutral cleaning agents, emulsion cleaning agents, and organic solvents cleaning agents.

The current cleaning process, whether it is alkaline cleaning or water cleaning, has mostly adopted spraying. The solution is directly sprayed on the substrate through the neatly arranged V-shaped nozzles with a certain pressure, and the dirt is impacted and washed, which greatly improves the cleaning. The cleaning time can be shortened, and the equipment layout can be more compact. This method is particularly suitable for the production of high-speed units.

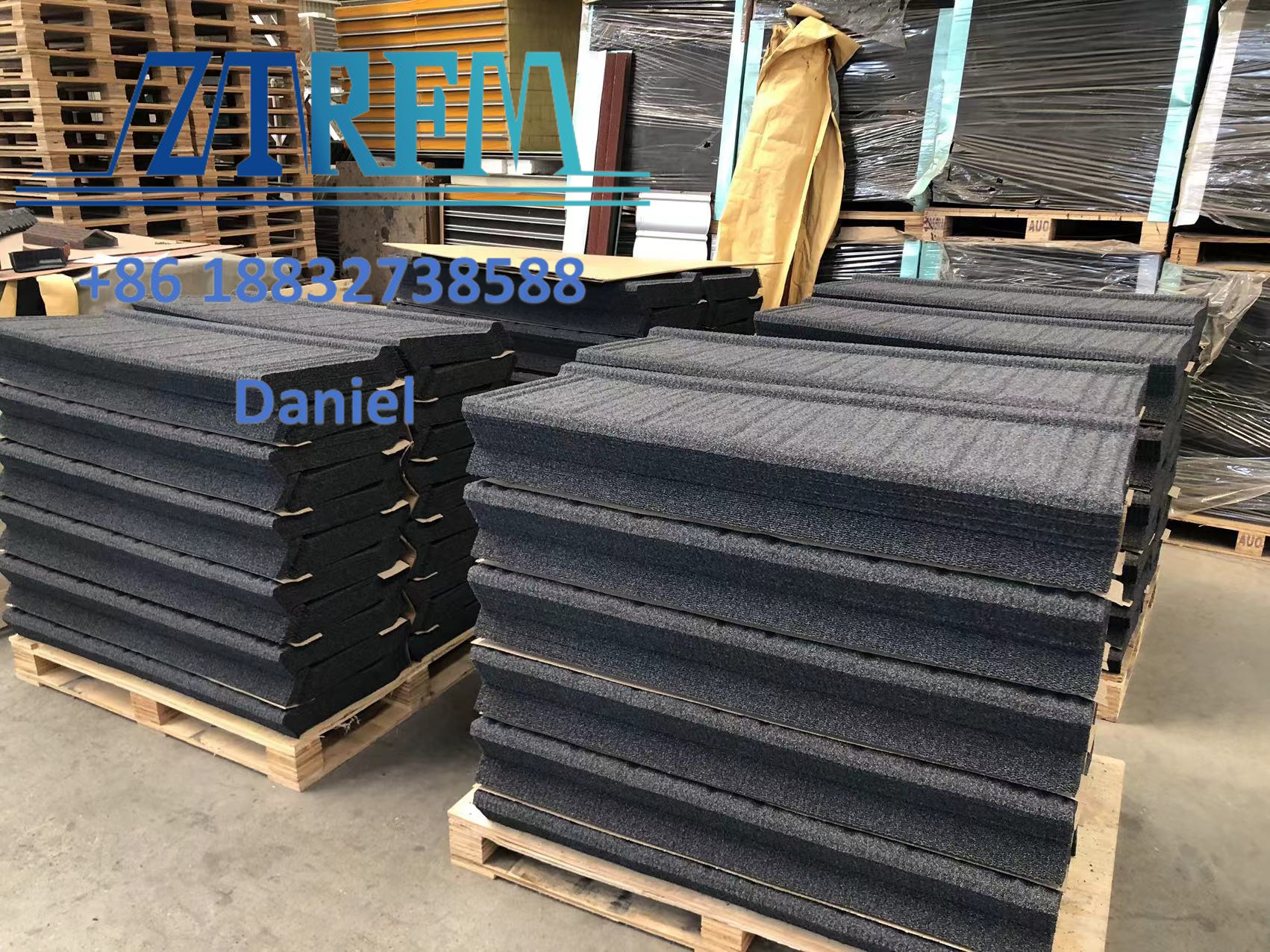

These our color coated roofing sheet roll forming machine pictures: